Compression: Mesh Convergence#

Simulation#

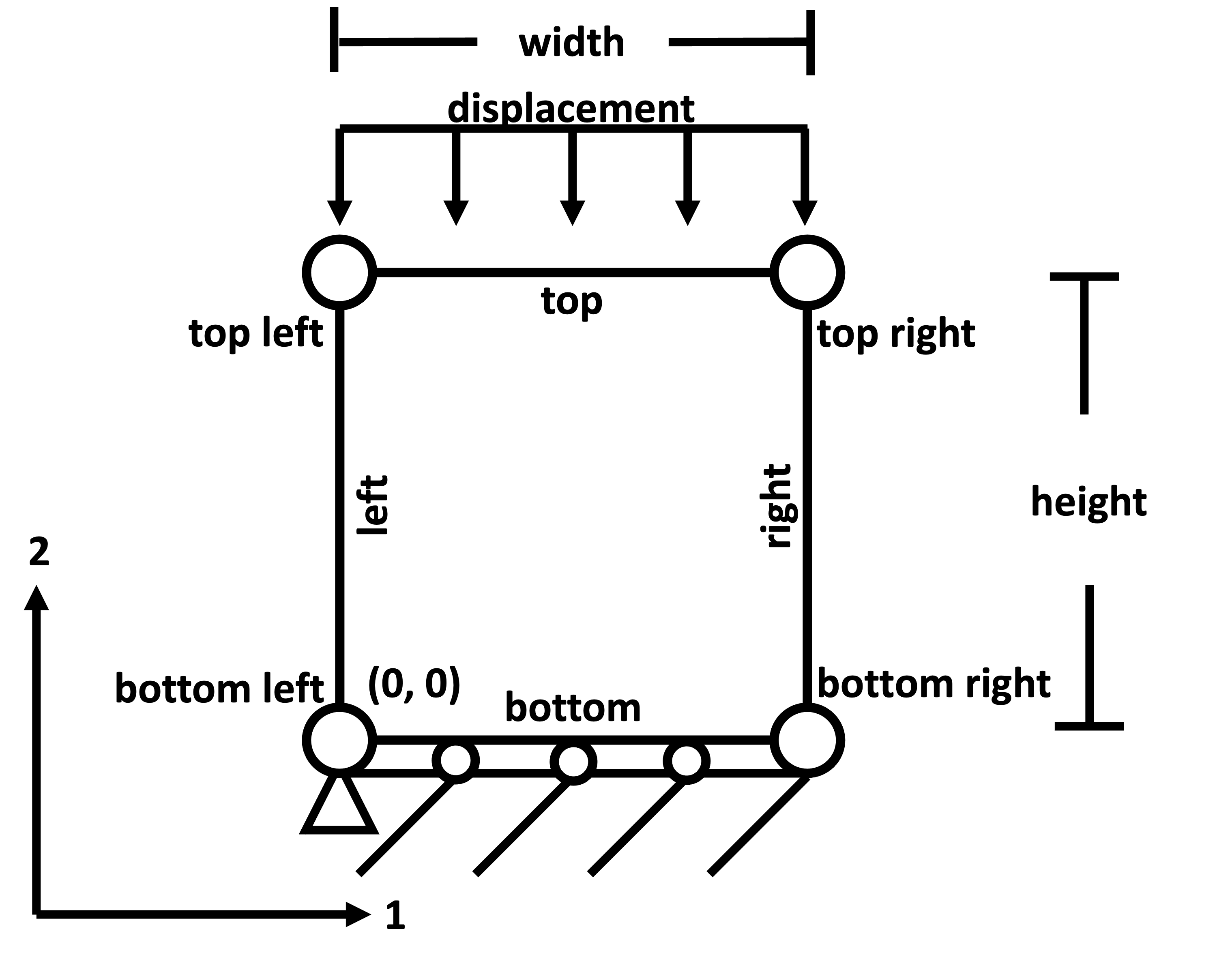

The rectangle model is simple demonstration for how to exercise the capabilities of a WAVES workflow [2]. It is a single 2D square, plane-stress element oriented in the 1-2 plane consisting of a mock, linear-elastic material model, simple boundary conditions, and applied uniaxial compression. The simulation preparation and solve are conducted in Abaqus [3].

Simulation schematic#

The rectangle model is comprised of a single 2D square part with nominal dimensions 1mm x 1mm, but which can be

parameterized by width and height by the journal file: modsim_package.abaqus.rectangle_geometry.

The bottom left node of the geometry is restricted in all six translational/rotational degrees of freedom using an encastre boundary condition. The bottom edge uses a roller boundary condition, with no translation in the 2 direction, but is free to move in the 1 direction.

Loading is prescribed as a uniaxial displacement of the top edge of the part in the negative 2 direction (compression), with a nominal displacement of -0.01 mm, which can be parameterized in the workflow.

A continuum plain stress (CPS4) element type is used for the rectangle model. The mesh convergence study varies the

mesh seed size through the global_seed parameter used by modsim_package.abaqus.rectangle_mesh. The mesh

convergence study includes four seed sizes in the table below.

Parameter Set |

global seed \([mm]\) |

0 |

1.0 |

1 |

0.5 |

2 |

0.25 |

3 |

0.125 |

A mock material definition was developed using the following parameters in the mmNsK unit system:

Parameter name |

Value |

Units |

Density |

2.7E-09 |

\([Mg/mm^3]\) |

Elastic Modulus |

100 |

\([MPa]\) |

Poisson’s Ratio |

0.3 |

\([-]\) |

Specific Heat |

8.96E08 |

\([mJ/(MgK)]\) |

Conductivity |

132 |

\([mW/(mmK)]\) |

Thermal Expansion |

23.58E-6 |

\([1/K]\) |

Theory#

For an isotropic, homogeneous solid under plane stress conditions at constant temperature, as assumed in the simulation problem description, the constitutive model for stress and strain is given by the equations [4]

In the case of unconstrained transverse expansion, the transverse stress \(\sigma_{11}\) is zero and the theoretical expected stress in the direction of the applied displacement, \(\sigma_{22}\) is given by

With the material parameters from the Material Parameters Table and an applied strain of

where \(L\) is the nominal starting height and \(\delta\) is the change in height, the expected stress for this simulation is

Results#

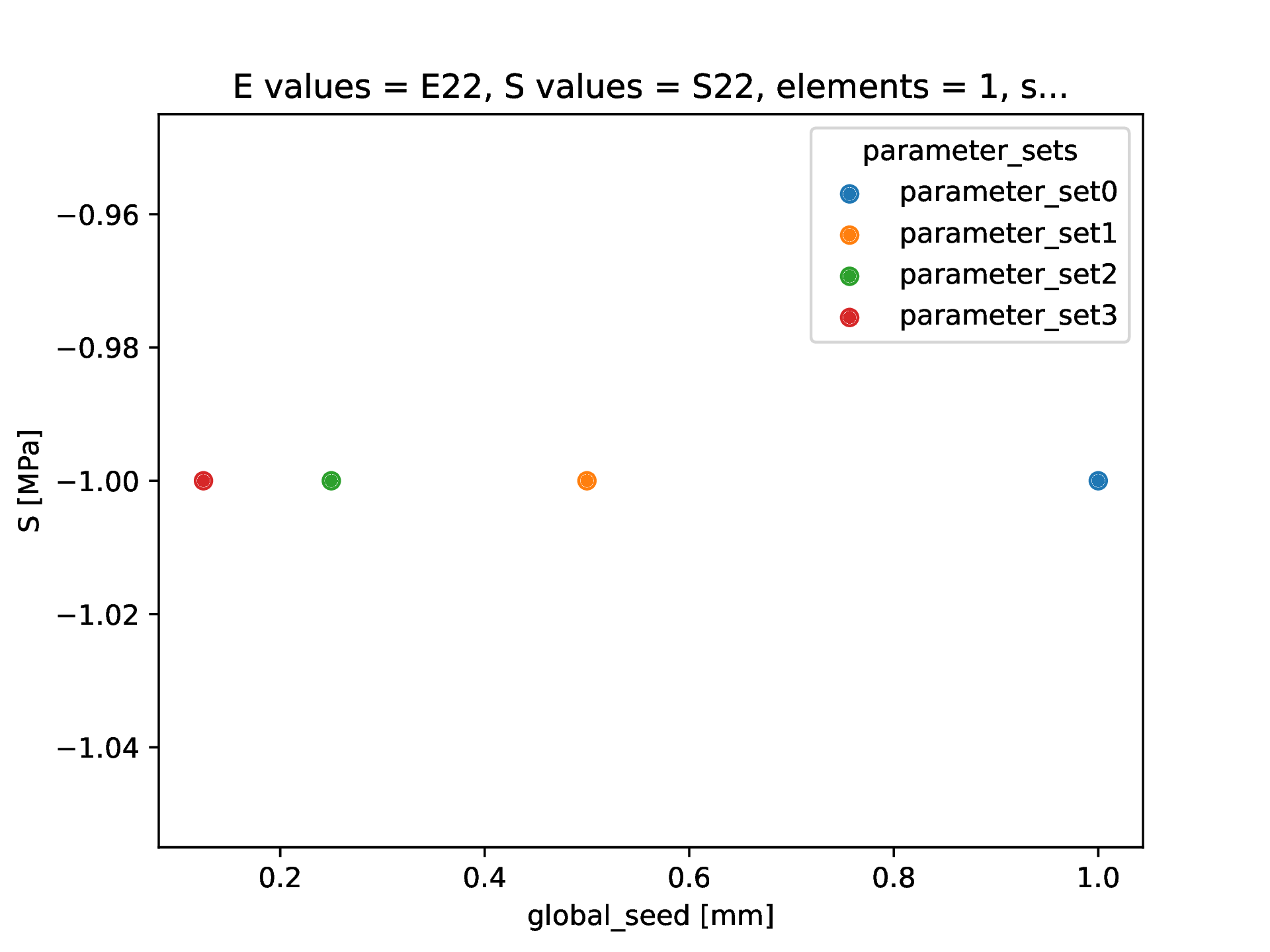

Stress mesh convergence#

Conclusions#

As expected from the simple loading and boundary conditions, the mesh convergence study shows that the quantity of interest (QoI), stress in the loading direction, converges with a rectangle. This verifies that the parameterized implementation of the load and boundary conditions correctly handles the mesh density and provides confidence in the simulation journal files for applications to future parameter studies of material properties and load.

Future Work#

Future work will apply more complex material models and a template sensitivity study between a more realistic QoI, structural strength, and the parameterized geometry, and material parameters. Following a sensitivity study, uncertainty propagation (UP) may be performed with representative bounds on input uncertainty, which will be stand in templates for known experimental measurement uncertain on the input parameters.